Travelling Faster with DSI: Gautrain High Speed Train

With approximately 1.4% of the surface area of South Africa, Gauteng is the country’s smallest province in terms of area. However, the province contains nearly 20% of the country’s population. Because the capital of Johannesburg is located in Gauteng, the region is also the financial and economical center of South Africa.

The province’s high population density is especially evident on the streets between Tshwane and Johannesburg. Today’s public transport systems are mainly dependent on the road network and contribute to high traffic density. In addition, approximately 30,000 cars use the traffic corridor between Tshwane and Johannesburg each week day.

The high traffic density was one of the main reasons for the decision to build a new high speed train network, Gautrain, in the province of Gauteng. The new transportation system will also provide economic advantages by improving infrastructure and by transporting the many tourists expected for the Soccer´World Cup in 2010.

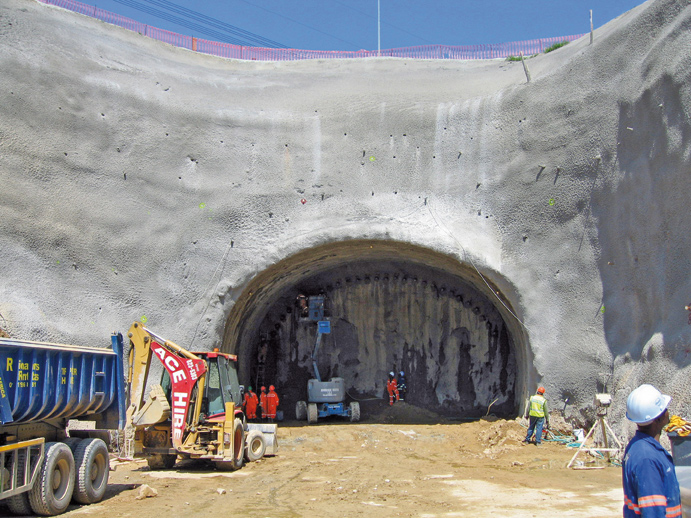

The 80km long route network consists of two lines, the first of which will create a better connection between the cities of Johannesburg and Tshwane (Pretoria). The second line will connect OR Tambo International Airport with Sandton, a northern district of Johannesburg. A total of 13km of the train route runs underground. The contractor was familiar with DSI’s specialist products from several past projects, which is why DSI was awarded a contract to supply tunneling products for this project as well. DSI South Africa and DSI Austria contribute to three of a total of ten planned train stations: Rosebank, Sandton and Marlboro Stations.

It is in these stations and the tunnel network that DSI Austria’s new AT-114 Pipe Umbrella Support System was used for the first time in South Africa. DSI supplied more than 5,000m of the AT-114 Pipe Umbrella Support System for tunnel advancement and also supervised on-site installation. The AT-114 Pipe Umbrella Support System is one of the most modern systems currently on the market. The selfdrilling system facilitates quick installation especially in difficult ground conditions and can be installed using conventional drilling machines.

DSI South Africa secured a 21 million Rand (approximately 1.8 million Euro) supply contract with the Bombela Consortium for the supply of 70,000 double corrosion protection (DCP) rock bolts for the Gautrain project over a period of 30 months. To date, 18,000 DCP rock bolts have been supplied. The rock bolt technology is used for the very first time in South Africa. This particular anchor type is ideal for complex engineering structures and aggressive environments where groundwater within the rock predominates.

Geological conditions are especially diverse on the 13km long segment that is to run underground. In many places, sandstone deposits cause unstable ground conditions. In addition, ground conditions at the Rosebank site are very sandy, and the water table is high. The double corrosion protection rock bolts are well suited for use in varying geological conditions. Due to differing geological conditions, anchor lengths varied between 2 and 10m.

Having adapted the lengths of the anchorages to specific requirements, DSI South Africa produced and supplied the rock bolts to the job site just in time.